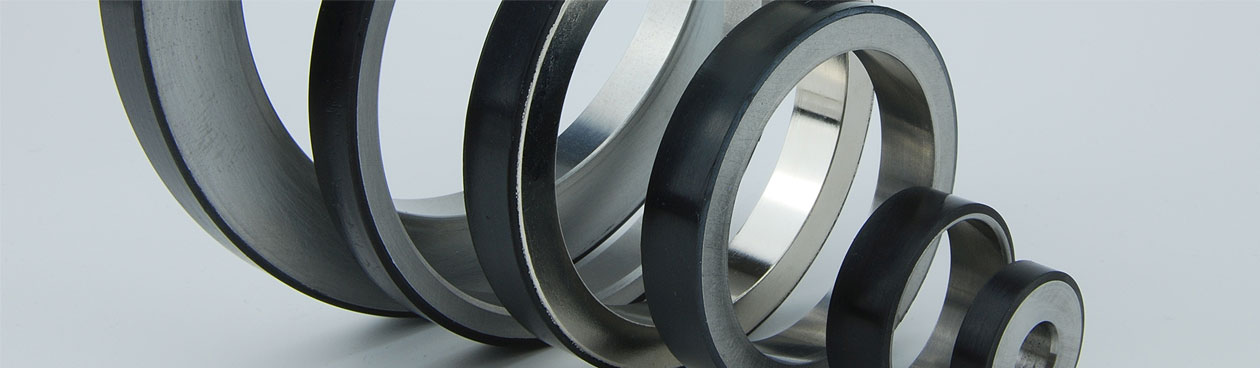

MAGNOPOL offers you magnetic scales to implement in magnetic measurement systems, usually in the form of pole rings (also called encoder wheels, magnet wheels or encoders). The magnetic coding stimulates touch-free field sensing sensor systems with hall or MR sensors. The sensors create a proportional electrical signal in the magnetic field or field direction.

The benefits of magnetic pole rings:

- Any desired resolution

- Excellent signal precision

- High speeds

- Excellent media stability

- Temperature range -40° to +160° CC

In the automotive industry, elastomer-based magnetic pole rings are state-of-the-art. They are used in combustion engines, transmissions or on axles in extreme operating conditions.

The magnetic measuring scales from MAGNOPOL have also established themselves in many industrial uses. That is how magnetic pole rings are successfully used in machine tools, robots, lift drives, solar applications, in wind energy and in aerospace.

In doing so, MAGNOPOL offers an inexpensive solution, even for smaller quantities – with all competencies necessary for this from a single source:

Information worth knowing on magnetic pole rings

Pole rings for magnetic measuring systems must safely and constantly represent their function as a measuring scale of measured values over their lifetime and under all operating conditions. There are special requirements stemming from this:

- High mechanical precision

- Safe and permanent connection between the magnet and metal stiffening elements

- Resistance to all operating conditions over its lifetime

- Homogeneous distribution of the ferrites and highly precise magnetisation for the best signal accuracy

The magnetic pole rings manufactured by MAGNOPOL have a high technological and application edge in comparison with traditional magnets for measuring tasks:

1. Through the material used:

Pole rings from MAGNOPOL are manufactured on a gum (or elastomer) base as the connection system for ferrites. Elastomers offer special material properties. The most outstanding characteristic is elasticity. Through this elastic connection system, the pole rings from MAGNOPOL are never brittle like other magnetic materials. In addition, MAGNOPOL uses special compounds with excellent resistance to thermal, chemical and mechanical influences.

2. Through the special moulding:

The chemical connection to the carrier material is created in vulcanisation, at 200° C and 300 bar. A bond like this is vastly superior to an adhesive in terms of strength and durability. The vulcanised elastomer layer on a metal carrier part allows for implementation of temperatures from -40° C bis +160° C. In doing so, the special moulding process takes care of the homogeneous distribution of ferrite particles. This is the basis of the high precision in the magnetisation.

3. Through the magnetisation procedure:

The application and the examination of the magnetisation takes place on specially developed systems. That is how one- or multi-track magnetisation takes place. The measurement scales are magnetically examined up to 100%; the measurement results are documented and archived.

4. Through the robustness:

Together with the sensor, the magnetised magnetic scales from MAGNOPOL can be operated with the system without joint housing or its own shaft in various media, such as oil, water, dust, etc. We use special antioxidants that ensure excellent protection against ozone and UV exposure in outdoor applications. This is the basis for the implementation of inexpensive bearingless measurement systems.