Incremental encoders

Encoders in the traditional sense convert rotation into an electrical signal that is proportional to the angle, speed or direction of rotation. The measurement procedure is optical or magnetic.

Due to their systems, optical encoders need their own housing. The code disc can be very precisely produced, but is very sensitive to impacts and condensation.

Magnetic encoders are more robust, but in terms of their mechanical construction, are as equally complex as the optical systems.

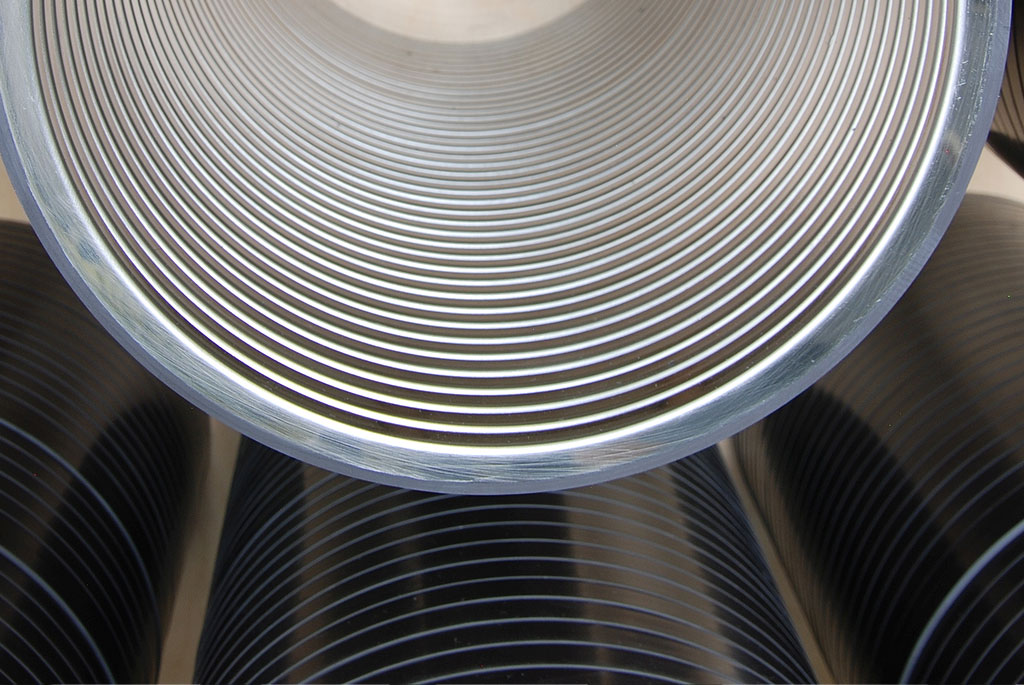

First, the robust MAGNOPOL pole rings make so-called bearingless measuring systems possible. These are only made up of a pole ring and the magnetic sensor. As a result, housings, bearings, sealants and shafts are not necessary and the measurement system becomes significantly more affordable.

The existing shaft is used to mount the pole ring. As a result, in addition to the simple compression connector, the pole ring can also be fixed using a clamp, flange bolting or pin connection, for example. In particular, the compression connector presents an elegant and affordable mounting method. Here, the elasticity of the magnets and the chemical adhesion to the metal part create the basis of a secure construction solution.

Absolute encoders

The magnet technology makes it possible to produce various pole patterns. This is the basis for simultaneously measuring various signals and converting them into absolute information. The necessary sensors contain the mathematical algorithms to fulfil customer requirements with regard to resolution and the type of signal.